- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

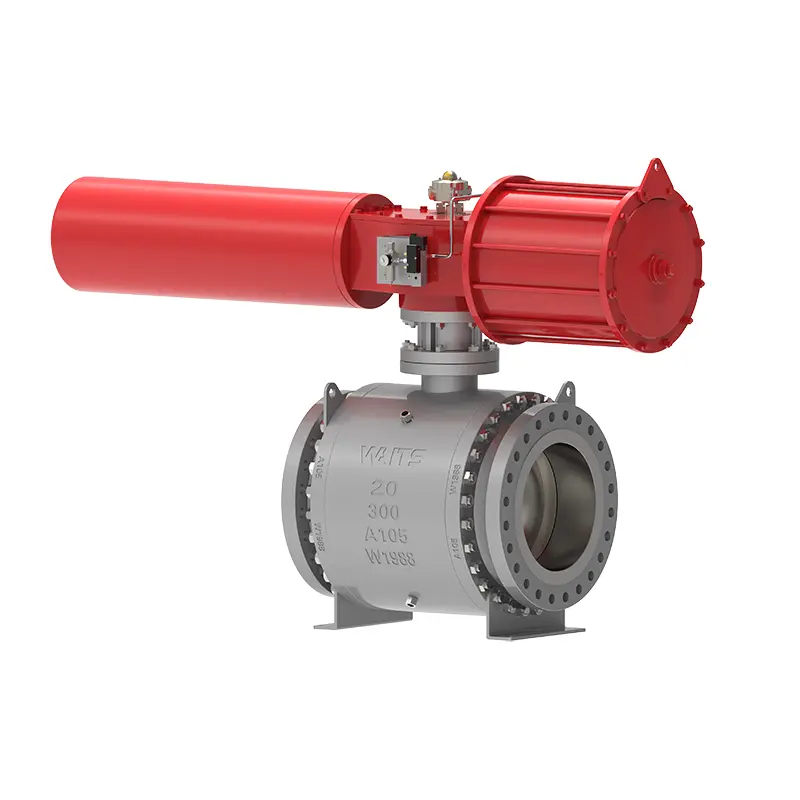

Fully Welded Ball Valve

Waits is a large valve manufacturer, and fully welded ball valve is one of the products we can provide. Since the valve seat of this product is composed of carbonized Teflon sealing ring and disc spring, it has strong adaptability to changes in pressure and temperature and will not leak within the marked pressure and temperature range. In gas transmission projects in the Middle East and heating projects in Northern Europe, fully welded ball valves are widely used.

Kirim Pitakonan

Katup bal sing dilas kanthi lengkap minangka produk tutup bal sing umum digunakake. Bisa nggunakake tekanan lenga utawa pasukan pneumatik kanggo ngontrol rotasi bal kanggo mbukak lan nutup lan nyetel tingkat aliran. Ing babagan kinerja, iku tahan karat, dipercaya ing sealing, gampang kanggo mbukak lan nutup, lan wis sawetara saka sudhut regulasi aliran. Mulane, digunakake akeh ing lapangan petroleum, industri kimia, gas alam, papermaking, perawatan banyu lan listrik.

The fully welded ball valve produced by Waits has excellent performance, compact structure, easy operation and long service life, all of which have passed our strict quality inspection system. During use, you can select the model according to factors such as media and operating conditions, and maintain the operating status of the ball valve through correct installation and operation, as well as subsequent regular inspection and maintenance. If you encounter problems, or want to know more about the product or the latest factory price, you can contact us at any time for communication and service support.

Standar Implementasi

| Standar desain | API 6D ISO14313, DIN 3357-1 |

| Standar flange | ASME B16.25, EN 12627 |

| Cara sambungan | BW |

| Testing lan acceptance | API598, API6D, EN 12266 -1 |

| dawa struktural | ASME B16.10, DIN3202, |

| Rating tekanan lan suhu | ASME B16.34, |

| Test tahan geni | API607, API6FA |

| Standar bocor sing kurang | ISO 15848-1, API 622 |

| Desain anti karat | NACE MR 0103, NACE MR 0175 |

Aplikasi

| Ukuran | NPS1/2~NPS56 DN15~DN1400 |

| Rentang tekanan | 150LB~2500LB,PN6~PN420 |

| Kisaran suhu | ;-40°C ~ +600°C |

| Range aplikasi | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Mode drive | Turbine, pneumatic, electric |

| Valve body/valve bonnet | ASTM A105/LF2, ASTM A182 F304/F316/F304L/F316L |

| Inti katup | ANSI304, A105/ENP |

| Batang katup | F6A F304 F316 F51 F53 Monel K500 |

| Valve stem nut | Paduan Tembaga |

| Packing | PTFE, PPL, RPTFE, Devlon, TEFLON |

Fitur Performance

Katup werni kanthi gandheng nganggo struktur awak tutup sing dilas kanthi lengkap lan kursi tutup tertutup (struktur sealing pirang-pirang). Loro-lorone desain mbantu supaya ora bocor. Batang tutup dirancang kanggo nyegah blowout. Yen operasi sing ora bener ditemoni, batang katup bisa dicegah saka njupuk metu saka awak tutup.

Katup dilengkapi piranti tahan geni lan anti-statis kanggo nyegah geni kanthi efektif. Katup injeksi pelumas diwenehake ing segel kursi tutup lan segel batang tutup. Nalika lumahing sealing rusak lan nyebabake bocor, pelumas sealing bisa disuntikake kanggo ndandani darurat. Katup ventilasi lan katup saluran diwenehake ing sisih ndhuwur lan ngisor rongga awak tutup kanggo njamin safety, linuwih lan penak.

Klep sing dikubur langsung bisa diwenehake. Operator ora perlu mlebu sumur. Dheweke bisa nggunakake gagang T ing sumur, sing trep lan aman. Struktur katup relief bisa disetel kanggo manajemen lan safety sing gampang.

Babagan efek piston kursi tutup: 1. Loro-lorone hulu lan hilir yaiku kursi katup efek piston tunggal, yaiku, fungsi DBB; 2. Loro-lorone hulu lan hilir yaiku kursi katup efek piston ganda, yaiku fungsi DIB-1; 3. Hulu minangka kursi katup efek piston siji, lan hilir minangka kursi katup efek piston ganda, yaiku fungsi DIB-2.